Every so often a development emerges that represents a true revolution. In the nineteenth century it was the onset of the “Industrial Revolution” with the dramatic advance of mechanization and the harnessing of electricity. The late twentieth century brought the rise of computers, while the introduction of the cloud in the early 2000s dramatically changed the way we store information. What could be next?

Welcome to Industry 4.0 and the emergence of the Internet of Things (IoT). Industry 4.0 relates to the way technology talks to each other and, according to the Chemical Industry Journal UK, the impact of innovation on industries (including the chemicals sector) is going to be enormous. Accenture estimates the Industrial Internet of Things (IIoT) could add $14.2 trillion to the global economy by 2030. Additionally, 87% of business leaders are confident that IIoT will result in the net creation of jobs.

Initially an initiative by the German government intended to further increase the competitiveness of the country’s industrial base, Industry 4.0 concepts have gained traction across much of Europe and around the world. In a challenging business environment, emergence of IIoT and digital technologies is a boon for chemical manufacturers to transition toward favorable business and operating models, according to Frost & Sullivan’s 2018 perspective “Redefining Chemical Manufacturing with the Industrial Internet of Things”.

Through IIoT, we are creating the ‘smart factory’ where systems communicate in real time via the Internet. Though this networked and highly integrated modality, supply chains can be shortened, processes optimized for maximum efficiency, and the customer experience (and your profitability) flourishes. Analysts believes that the chemical sector can lead the way. With more than 20 million people employed, annual sales of $5 trillion and clients in everything from agriculture and automotive to construction and pharmaceuticals, changes in the chemicals industry are likely to have a ripple effect on a number of other industries.

The key advantage with these revolutionary technologies is that they integrate various functions across the value chain, establishing a digitally connected ecosystem in the chemical manufacturing environment. Chemical enterprises are well positioned to increase their production throughput, enhance asset lifecycle, maximize resource utilization, and achieve operational efficiency. This is imperative especially in the present market scenario that demands shorter innovation cycles, superior quality at optimal cost, and reduced time-to-market. IIoT serves as a nervous center offering end-to-end support right from product development, planning, and scheduling and commissioning to production, packaging, inventory management, and marketing and distribution.

In “Catalyzing Transformation Through Operations Improvement and Business Growth,” Deloitte points to BASF as one innovative company using advanced analytics for predictive asset and management of their processes. Examples include BASF’s sustainability platform incorporating 4.0 elements such as the Sustainability Metrics And Reporting Tool (SMART) for supply chain operation and information services, Power Plant 4.0, and Waste Management 4.0. BASF is using Industry 4.0 applications in its deployment of connected systems and advanced analytics models for predictive asset management, process management and control, and virtual plant commissioning. Moreover, assessing the benefits of digital chemical plants that boost overall efficiency, several industry giants such as, DuPont, Dow Chemicals, Evonik, and Covestro and Clariant are actively investing in IIoT solutions. Such investments are expected to record an uptake in the forthcoming years as chemical enterprises strive to develop innovative and sustainable chemicals following efficient and safe processes.

The time is ripe for transformation. Advanced technologies relevant to the chemicals industry have reached a level of cost and performance that enables widespread applications, pushing for even greater adoption.

Is your business aligning and investing for this revolutionary wave?

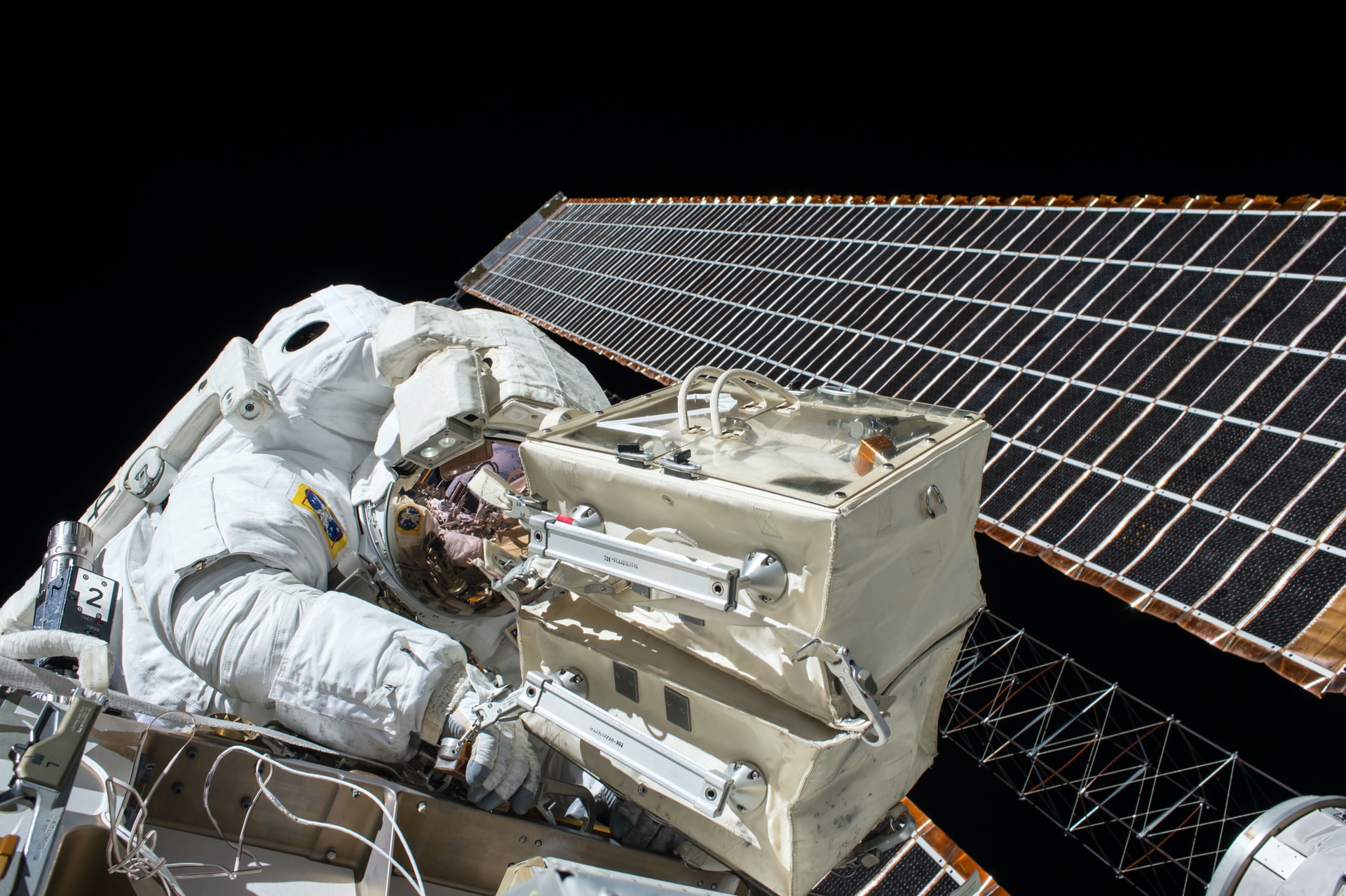

Photo Credit: Chemical Industry Journal UK